Business introduction

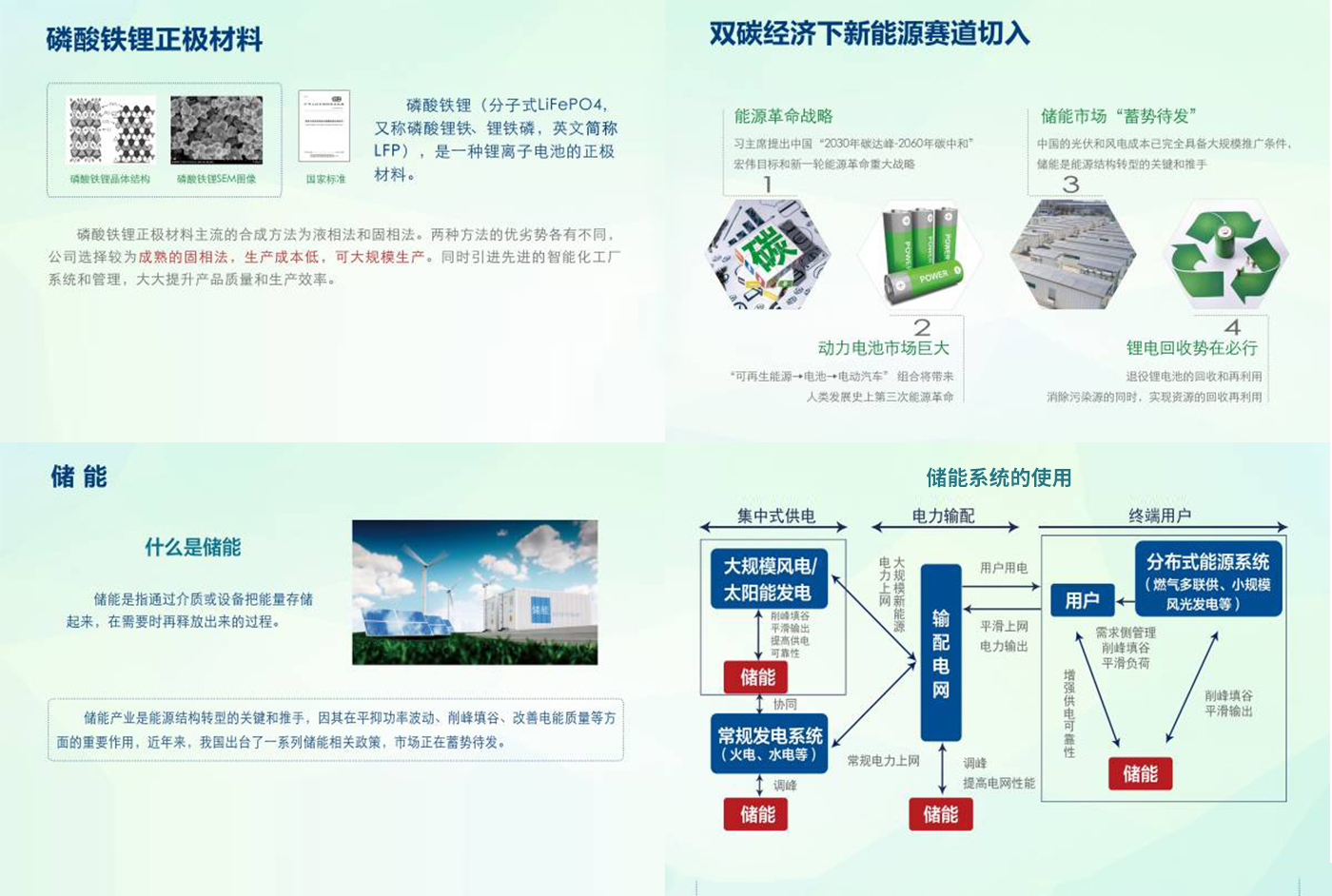

In order to seize the development opportunities of the new energy industry, the company quickly cut into the new energy material track, actively layout the lithium ion battery industry, and seek the development opportunities of the material industry in the upstream and downstream industrial chain, respectively planning and constructing the project of 500000 tons of high-performance lithium iron phosphate (LFP) new energy battery cathode material and the project of 200000 tons of power energy storage battery cathode material integration, focusing on the research, development, production and sales of lithium ion battery positive and negative core materials, Relying on the advantages of all parties and driven by technological innovation, optimize the strategic layout of the new energy industry, and strive to become an "intelligent manufacturer" providing new energy material solutions.

Technical advantages

1、 Lithium iron phosphate (LFP) new energy battery cathode material

The introduction of internationally advanced lithium iron phosphate intelligent complete set of equipment, the adoption of the unique nano-sized "solid phase synthesis" process technology, the three main raw materials of iron phosphate, lithium carbonate and organic carbon source, through the production process of high-precision batching, nano-scale grinding, precision calcination and fine grinding, the lithium iron phosphate cathode material has the performance advantages of high energy density, good cycle performance, safety and stability, It is widely used in lithium battery fields such as new energy vehicle power battery, energy storage battery and 3C electronic products.

2、 Integration of negative electrode materials of power energy storage battery

The company adopts domestic mature process technology to build a high-level production line of negative electrode materials in China. The main equipment adopts the internationally advanced third-generation improved reactor, the internationally advanced carbonization furnace technology, and the high-efficiency improved graphitization furnace and process. The product quality is stable, the ratio is increased, and the cycle is increased; The products are finally applied to power (electric vehicles, such as new energy vehicles, electric bicycles, etc.), 3C consumer electronics, industrial energy storage and other fields.

3、 China's first CKB lithium battery recycling project

The company, together with Kawasaki Heavy Industries of Japan, jointly developed the CKB lithium battery recycling pilot project, creating the world's first set of roasting process to dispose of waste lithium batteries. The main process technology of the project extracts valuable metal lithium through preheating and decomposing the electrolyte, crushing and screening, roasting, dissolution, pressure filtration, evaporative crystallization and other processes of waste lithium batteries. At the same time, it makes full use of the high temperature and low oxygen heat source of the cement kiln to reduce energy consumption. Pyrolysis of toxic waste gas is safe and efficient, low carbon and environmental protection. It is "China's first and the world's leading".